QUALITY AND GUARANTEE AT YOUR SERVICE

WILLET 50 is a team of experienced and passionate professionals, specialised in the field of electroplating. We offer the best professional and differentiated service, based on quality, guarantee, advice, close and personalised treatment and attention to every detail.

DEGREASE

The first step is to remove the external and internal grease from the parts. For this we use chemical and cathodic degreasing techniques.

ZINC REMOVED

We then clean any zinc, scale, rust, etc., leaving the parts ready for pickling.

PICKLING

In this process we continue to remove impurities and activate the surface of the parts for subsequent zinc plating.

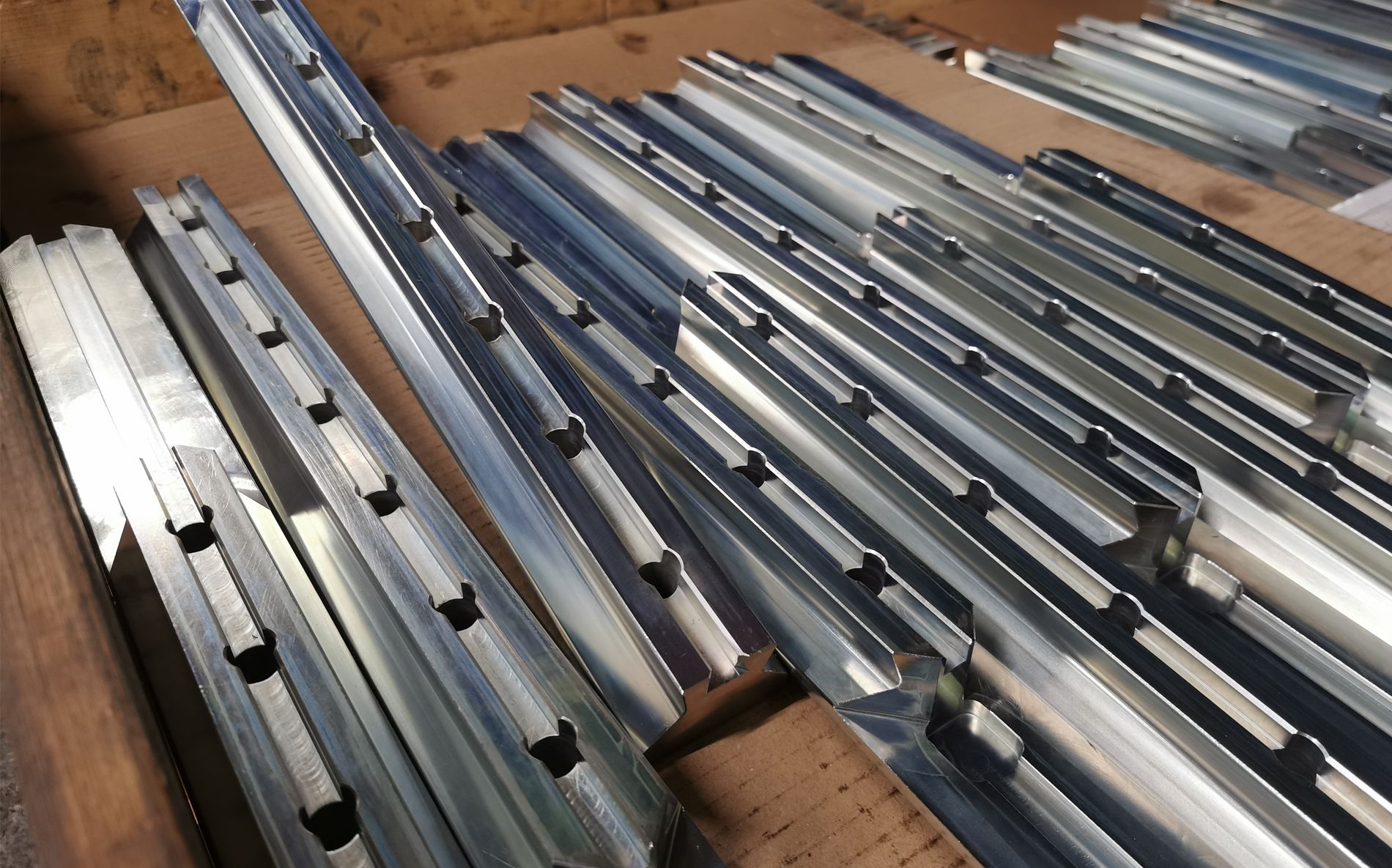

ZINC PLATED

At this point we add zinc to the parts using the electrolysis technique. We cover all types of metal parts.